Pipeline Rehabilitation

Pipeline Rehabilitation

Pipeline Inspection & Condition Assessment

- Ultrasound Material Thickness Gauge

- CCTV Inspection

- Ground Penetrating Radar

- Pipe Cable Locator

- Pipe Laser Profile

- High Pressure Water Jet Cleaning

- Aerial Photography Service

- Quick Water Test - eXact iDip

Leakage Detection & Monitoring

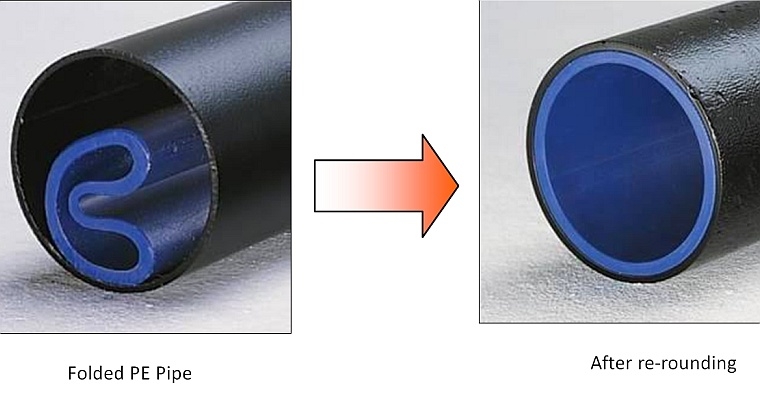

Compact Pipe had been widely used in many WSD’s contract to rehabilitate smaller size (300mm or below) water main in Hong Kong. Compact Pipe is a close-fit lining technique with continuous string of polyethylene pipe, folded into a ‘c’ shape along its length. This compact shape is created during manufacturing, when the pipe, while it is still hot, is folded. It is supplied from the manufacturing plant wound on a drum. Through its folded shape, the pipe has become substantially smaller in cross sectional area, allowing it to be easily inserted into the existing pipeline.

On site the pipe is taken directly from the drum, which for that purpose usually is held by a dispensing unit on a trailer. The winch cable can be connected to the pulling head fixed to the pipe. The pipe’s axial flexibility allows direct insertion via small sized access points, such as manholes in the case of sewers, thus avoiding any excavation work and becoming a true no-dig method. Once pulled in, the ends are sealed and a purposely built installation unit is activated to supply steam and compressed cheap replica watches air. Steam is fed into the pipe to trigger off the memory of the plastic, making the pipe revert to its original ‘o’ shape.

Subsequently, pressurised air is led in, to make the pipe close fitting with the inside bore of the existing pipeline. The result is a new structurally self-supporting pipeline inside the old deteriorated one. Compact Pipe is especially advantageous where the pipeline is not accessible or where there is heavy traffic so that open trench construction is not possible. Compact Pipe only require small footprint of launching and receiving pits, which can even be omitted completely in the case of a sewer pipe rehabilitation where the existing manholes can be used.