Pipeline Inspection & Condition Assessment

Pipeline Rehabilitation

Pipeline Inspection & Condition Assessment

- Ultrasound Material Thickness Gauge

- CCTV Inspection

- Ground Penetrating Radar

- Pipe Cable Locator

- Pipe Laser Profile

- High Pressure Water Jet Cleaning

- Aerial Photography Service

- Quick Water Test - eXact iDip

Leakage Detection & Monitoring

Avoidance of pipeline damage during trench excavation is one of the major challenges faced by excavation contractors. A pipeline damage risk management system should include necessary procedures to locate underground utilities at exact excavation areas by using Pipe and Cable Locator (PCL) which is authorised for use in Hong Kong. However, there is a major limitation of PCL that it only applies to metallic utilities. Now, we provide alternative locator for pipes made of various materials namely Ground Penetrating Radar.

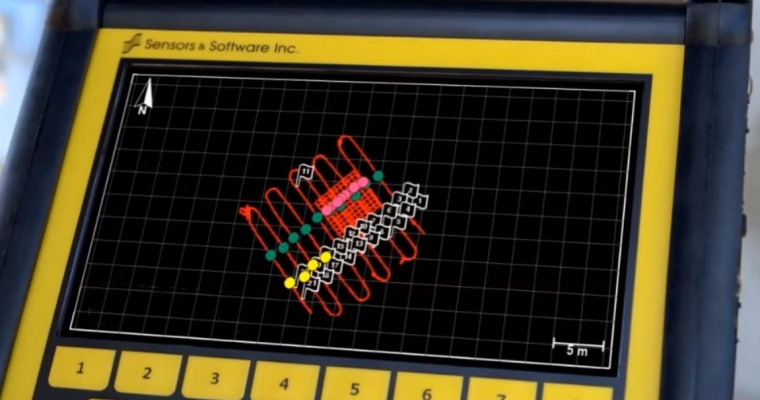

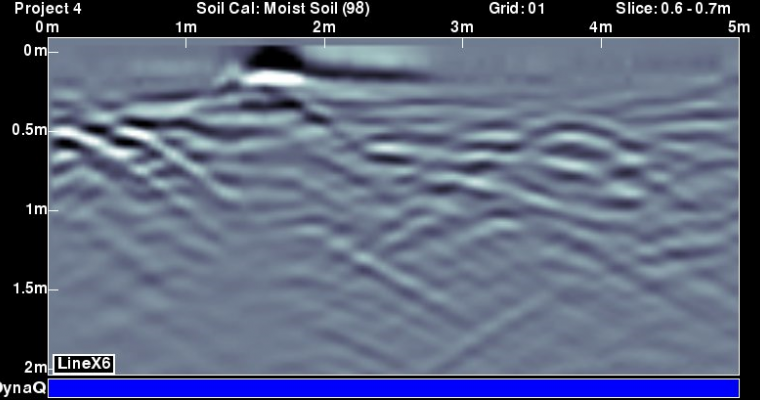

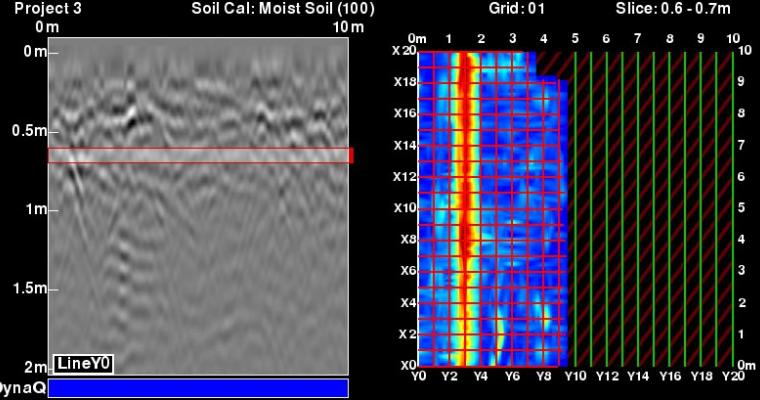

Ground Penetrating Radar (GPR) is a non-destructive testing (NDT) method using electromagnetic fields to detect structures by measuring the changes in different permittivities of material. The applications of GPR include voids detection, underground utility mapping, reinforced concrete condition survey, and pipe leak detection survey. Innopipe offers the service of collection and interpretation of GPR survey data.

Why use Ground Penetrating radar?

Nowadays, plastic pipes (UPVC, PE, ABS etc) become the majority of pipe laying network for various utilities in Hong Kong. Ground Penetrating Radar is most suitable to locate non-metallic and metallic utilities of which survey data can be interpreted in 3-D view.

Services We can Provide...

Utility Locating / Mapping

GPR is time-saving and precise in scanning large scale utility alignment works for newly developed area of mapping. It is SUPER effective and accurate to provide on-site underground pipeline condition for excavation works. Moreover, it is compatible with drawing software (e.g. AutoCAD) to generate underground profile in both 2-D and 3-D views.

Leak Detection

Considering leakage detection, GPR mapping is based on the soil / groundwater conditions, and analysis of leak intensity by software to pinpoint the leak location.

Structural Analysis

- Voids Dectection

In order to prevent road subsidence, GPR is used to detect the void. The position, diameter and depth of void can be estimated by data analysis and repair work can be conducted according to the result.

- Reinforced Concrete Condition Survey

GPR is used in rebar scanning covered by concrete. With rebar mapping results showing in grids on the concrete surface, it ensures the safety and efficiency of drilling work that safeguards cheap rolex replica the integrity of structure and minimizes remedial repairs or patching.

Benefits of GPR:

Quick Analysis

For accurate surveys, trial pit is mostly used to verify the exact depth and location of utilities. GPR implements advanced software to interpret signalling into different layers under depth in 3-D view cube.

Effective Cost

GPR provides large area scanning in grid line analysis.