Pipeline Inspection & Condition Assessment

Pipeline Rehabilitation

Pipeline Inspection & Condition Assessment

- Ultrasound Material Thickness Gauge

- CCTV Inspection

- Ground Penetrating Radar

- Pipe Cable Locator

- Pipe Laser Profile

- High Pressure Water Jet Cleaning

- Aerial Photography Service

- Quick Water Test - eXact iDip

Leakage Detection & Monitoring

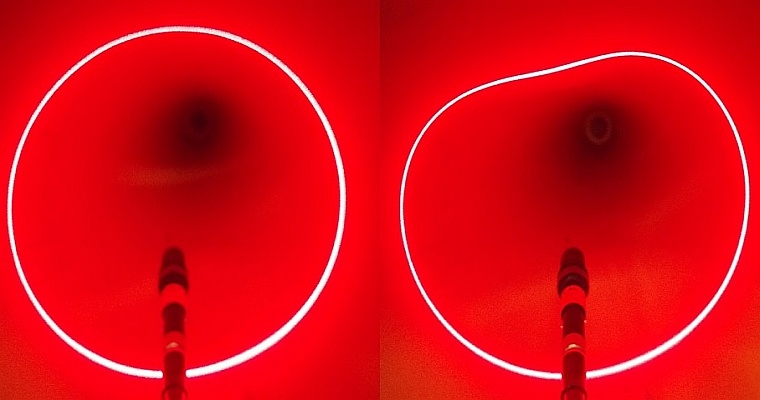

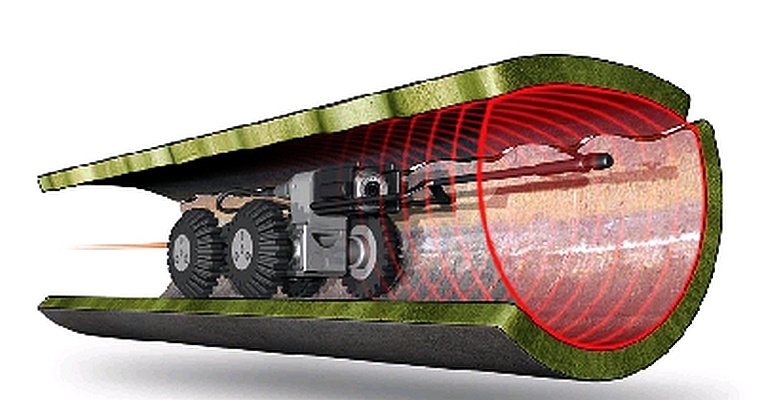

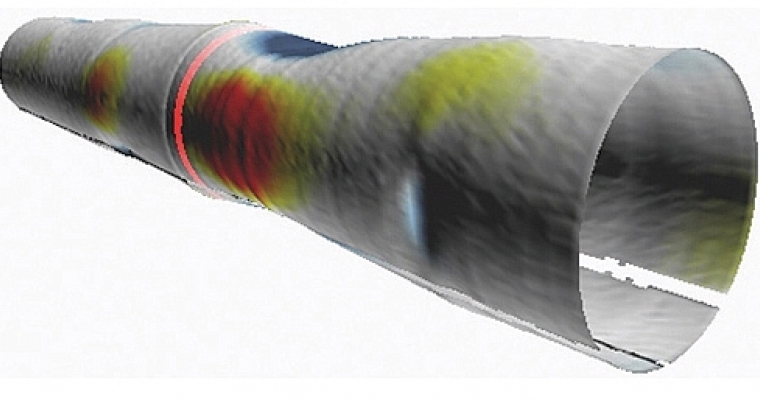

Innopipe provide pipe laser profile service to determine profile measurement of the existing pipe. Pipe defects such as partially collapsed or distorted pipe are very difficult to determine through a CCTV inspection, and the laser profile will provide detailed documentation of the pipe profile along the entire length of the pipe.

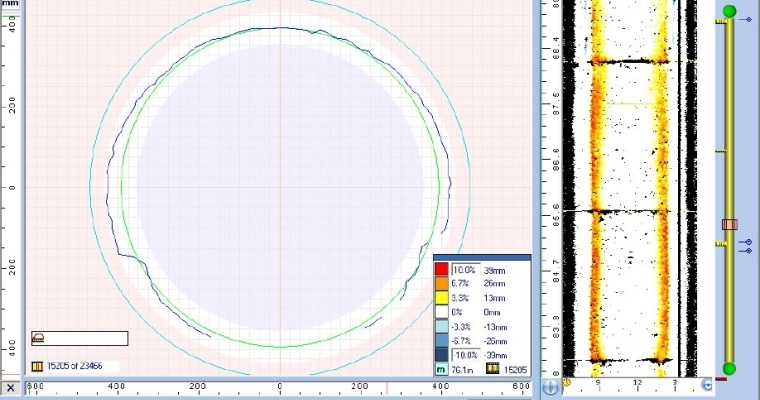

Innopipe certified technicians collect survey data and create pipeline reports containing the measurement of defects and other features inside the pipeline. This includes measurements of pipe size, tees, water levels and other features, as well as automatic analysis of pipe ovality and capacity up to 30 times per second. The resulting CCTV images are then analyzed using innovative software.

Precise measurements can be taken from a single frame captured from the prerecorded or live video. This captured frame, with its measurement data, can then be stored as a JPEG or BMP file. Manual measurements can be performed on the captured digital profile to an accuracy of 1mm.

For pipe rehabilitation, laser profile will provide more detailed information about the host pipe's circumferential profile allowing for a more accurate pipe liner design by the engineer. After the renewal pipe is installed, the laser profiler will then document the condition of the new pipe as it relates to the existing host pipe.